CNC Consultation

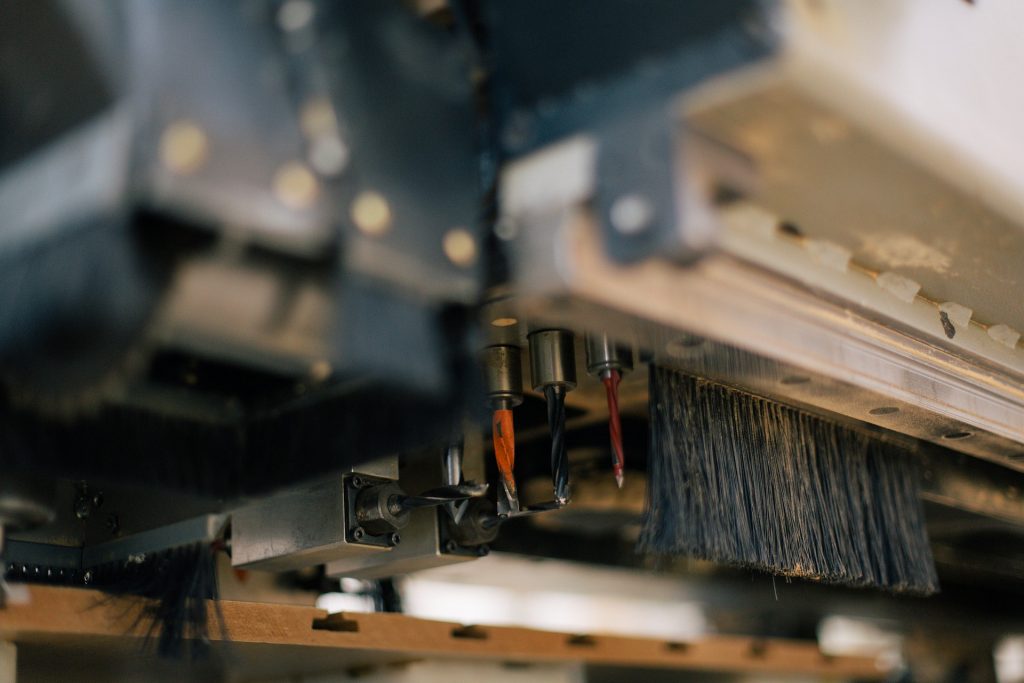

Buying a CNC machine is one of the biggest investments you’ll ever make for your business. That’s why you should consult the professionals at CNC Woodworking Master before spending your hard-earned dollars.

Our experienced team is here to walk you through the pros and cons of various brands, as well as pricing, maintenance and more. After the consultation, you’ll have a clear idea of which CNC machine is the right one for you and your business.

Undergoing a CNC consultation will help you pick a good quality machine that will last a long time. Here are a few essential things to consider when making your selection:

Machine Weight & Materials

Several different materials are used to make CNC machines. Each one is suited for a certain type of job. The most common materials are aluminum, composite, iron cast and polymer. Tough jobs require a much more durable material such as iron cast. The other materials can handle almost all other tasks you need to be completed.

Work Radius

You should always get a CNC machine with a working radius that’s larger than the biggest materials you’ll use. There’s nothing more frustrating than being in the middle of a tough job and finding out you don’t have the right workspace to get it done! Going with a large work radius ensures you’ll never have to worry about coming up short on promises to your clients.

Machine Speed

Do you have the need for speed? It’s important to look at the feed rate of the machine, also referred to as the speed of the machine. The feed rate will dictate how fast you can cut materials during manufacturing. If your CNC jobs are more spread out, you might not need to pay more money for a faster feed rate.

Spare Parts

This aspect of CNC machine ownership is crucial. Investigate whether or not it’s easy to find spare parts for the brand you want to purchase. Are the parts very expensive? Can you get them shipped to your shop quickly? Are they easy for a technician to repair? This is essential because every hour your machine is down is costing you money. Some brands are more repairable than others.

Power Usage

You can buy the nicest CNC machine on the market, but it will be useless if you don’t have the proper power supply. Be sure to determine if your shop can supply the power needed to operate your desired CNC machine. If the specs don’t match up with the power requirements of your desired model, you’ll need to contact a licensed electrician who can make the necessary upgrades to your workspace.

Call CNC Expert

If you want to buy a CNC machine, make sure you do your research first and call up the team at CNC Woodworking Master. Our experts will walk you through the process of buying a CNC machine that meets all of your needs. We’ll run your requirements through our industry-leading assessment system to make sure you’re not spending more money than you have to. Contact us today for a free consultation.